What is Quality Management? Definition, Components, Principles, and Importance

What is Quality Management?

Quality management is a process of planning and managing quality standards in the organization. It includes overseeing all organizational activities to maintain the desired level of product or service quality.

It is a management tool that focuses on both service and product qualities and how to achieve them. It is achieved through its four main components i.e. setting quality plans, implementing them, assuring the plans, quality control, and quality improvement.

More simply, it is a process of creating plans that specify the requirements to be followed in the planning, manufacturing, product handling, delivery, and follow-up after the sale of goods and services known as quality management.

It involves meetings to decide on the quality requirements outlined in the quality management plan, the process of establishing who would be involved in managing quality and their specific responsibilities, and the process of defining the metrics that are used to measure quality.

QMS, quality management system is the alternative name used for it which is a structured system that outlines policies, procedures, and processes for achieving quality standards.

Components of Quality Management

A good quality management solution is simple and effective enough to meet the changing expectations of customers. The following are the main components of a quality management system.

Quality Planning

Quality planning is the process of setting directions and steps to be taken to produce the desired quality products. It is effective when it is linked with the company’s vision and mission statements.

Under this planning, quality standards are set, necessary requirements to meet those standards, and measures to check such standards to ensure qualities are being met or not.

Related: Dimensions of Quality

Quality Control

Quality control involves checking and inspecting products in the physical field to check if the products made met or not the standards outlined in the planning.

Using of quality control methods depends upon the nature of the products. For instance, in construction, it may include checking of strengths of concrete, machines, and equipment. In service, quality control may include how courteous and polite employees are while serving customers.

Quality Assurance

Customer confidence in a brand’s level of excellence can be raised through quality assurance. It can be employed as a productive method of creating a favorable brand image.

While quality control is inspecting the product or service to ensure the quality is met or not whereas quality assurance is reviewing delivery services to ensure the stated quality reaches customers.

Quality Improvement

Once the quality control process is completed, it is necessary to review the performance of the product and finding out new solutions to go forward. A successful company always looks for continuous improvement in its products. Assess how the previous quality system worked and how it impacted the company’s financial statement.

Read Also: What is Core Product?

Principles of Quality Management

The main purpose of quality management is the continuous improvement of product or service quality to meet the changing expectations of customers. The basic principles of quality management include.

- Improvement – A company should focus on continuous improvement for success in the long run.

- Customer Focused – Product or service quality should be based on the customer’s needs and expectations of standard. Satisfied customers are essential for the success of the firm.

- Change in Culture – When culture is changed employees should be socialized about the new culture of the organization.

- Employee Involvement – Management should implement a participative approach in each and every activity of the organization. In such situations, employees devote their best effort to quality management.

- Prepare Strategic Plan – The Company must have a vision and mission for quality management. It should focus on long-term performance and develop strategic plans to achieve it.

- Team Work – The practice of teamwork and group work must be encouraged.

- Efficiency Development – Workers and management should be aware of how new methods and technology can be used to improve product quality.

- Mutual Relations with Suppliers – When a company has a good relationship with suppliers it is sure that only good raw materials can come to the organization.

- Focus on System Approach – Management should develop a system to develop input into output.

- Emphasize Transformation – All organizational members must have an understanding of each other and work together to reach quality goals.

- Leadership – Strong leadership is important in an organization. Leaders at all levels should foster an environment where people are motivated to work toward the company’s quality goals.

- Evidence-Based Decision-Making – The company should make decisions based on the analysis of data and facts only.

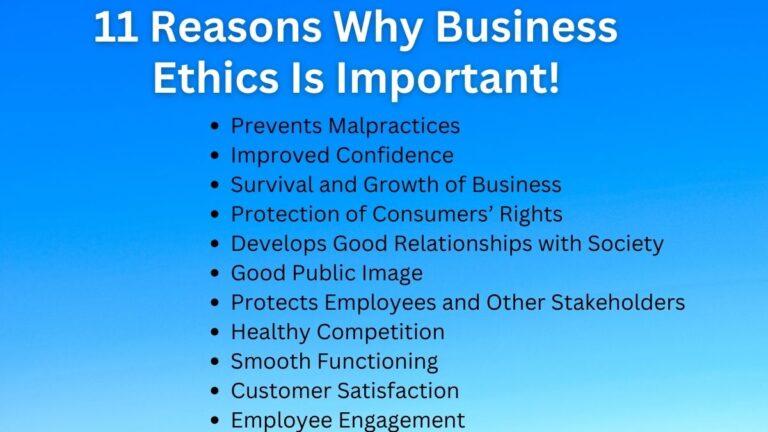

Importance of Quality Management

The following are some importance of quality management in organizations.

Customer Satisfaction

Quality management ensures the availability of quality products in the organization. As such, customers get quality products as they expect which increases their satisfaction level.

Lowers the Cost

Regular review of the production process to the delivery process helps to highlight the management where defects lie and take corrective measures if needed. Resulting in lower production costs and other costs.

Effective Utilization of Resources

The quality control system ensures careful study of each and every aspect while employing resources to produce finished goods. Regular review is made during the production process, wastages are minimized ASAP, and efficiency is maintained.

Builds Good Image

Good quality products and consistency of the organization to provide the same quality products build a good image in the community.

Competitive Position

Quality of the product or service also helps the organization to build a competitive position in the organization. For this, the organization should study the market and competitors’ strategies and continuously improve its product quality.

Read Next: What is TQM?

Sajan Kushmi is a content writer with more than 4 years of experience. He holds BIM Degree. He write on the topics related to Management, Marketing, and Entrepreneurship.