Process of Controlling Function of Management

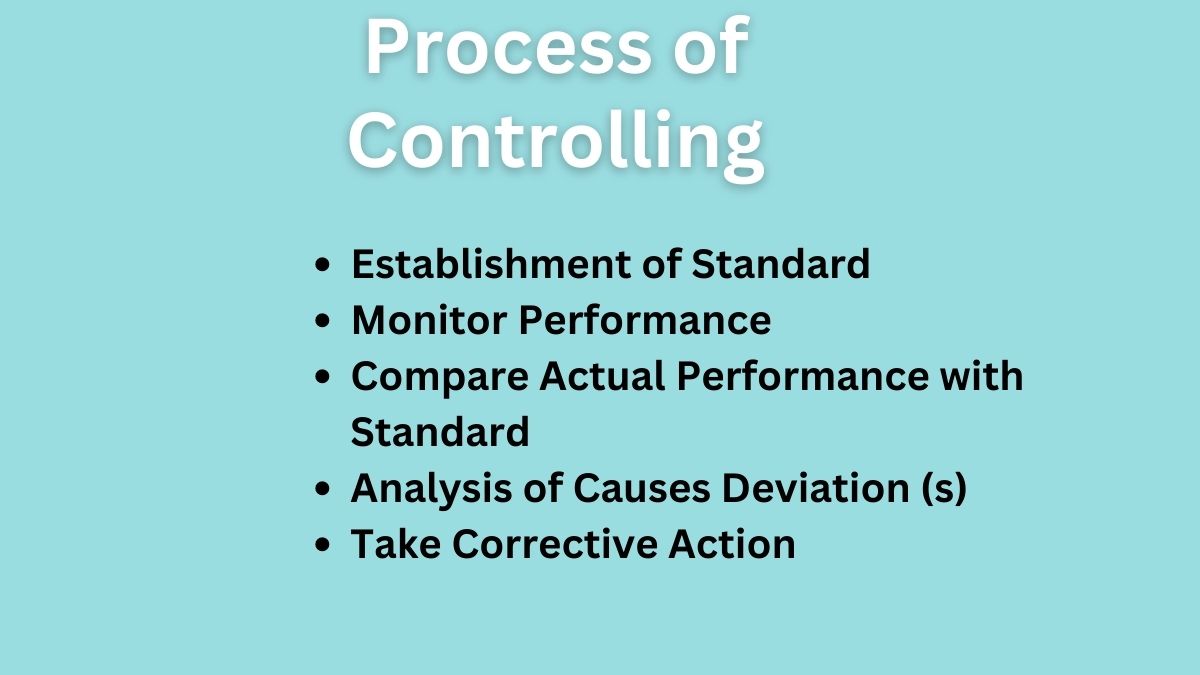

Process of Controlling

The controlling process includes a series of steps, from setting standards, measuring performance, finding causes of deviation, and taking corrective actions.

Controlling is an important management function to ensure the achievement of organizational desired goals as planned. The following five (5) are the main steps in the controlling process for making controlling deficient, effective, and productive.

Establishment of Standard

The pioneering step of the control process is establishing a performance or output standard. The standard acts as a criterion against which the performance of managers, employees, departments, or the whole organization is judged.

Standard criteria are mainly of two types – tangible and intangible. Tangible standards are those which can be expressed or measured in numerical terms. For example, cost, revenue, profits, production units, sales units, time, etc.

On the other hand, intangible standards are those which can not be measured or expressed in numerical terms. For example, employees’ morale, employee satisfaction, the attitude of employees, the company’s image, public relations, and so on.

Managers have to set both tangible and intangible standards. Both have a significant impact on the performance and success of the organization.

When standards are set controlling becomes easy because it is exercised on the basis of these standards. As a manager, you should set control standards SMART i.e. they should be specific, measurable, attainable, realistic, and time-bound. You should avoid setting over-ambitious and unrealistic standards.

Related: Characteristics of Controlling

Monitor Performance

The second important step of controlling is the monitoring of performance. As setting goals and standards are part of the planning process, it is equally important in controlling also.

Once you have set the standard of control and the plan is implemented, your next task is to the monitoring of performance and keeping records. Doing this helps you to measure actual performance and compare it with the standards you have set.

Measurement of quantitative i.e. tangible standards is easy as it can be easily expressed in money, cost, unit terms, etc. Measurement of intangible standards would be difficult for you. For this ask employees how their attitude toward the standards, work environment, their relations with superiors, etc.

Compare Actual Performance with Standard

Comparison of actual performance with that of the standard is an important step in the control process to identify weaknesses and strengths in any part of the performance.

After comparing actual performance with the standard, the deviation is identified if any. The deviation is a gap between the actual and standard performance.

Once you have measured the performance in the second step, this step includes a comparison of actual and standard performance and finding if any deviation exists or not. If the deviation between standard and actual performance is within the acceptable range, the goal achieved is close to the standard target.

And, if the deviation between the standard and actual performance is far away from the acceptable range. Such deviations should be noted and analyzed, and further corrective steps should be initiated.

Related: Planning Process

Analysis of Causes Deviation (s)

There can be many causes of deviation that prevent the actual performance from reaching the standard. The causes may include improper planning, changes in government policies, changes in market conditions, changes in competitors’ strategies, because of outdated technology, lack of coordination, etc.

There may be one or various reasons for deviation – finding out where the problem lies and why helps to take the right corrective action at the right time.

Take Corrective Action

The final step of the controlling process is taking corrective action (s) so that the actual performance comes to the range of standard. It is necessary to initiate corrective action to make sure the goals will be achieved within the stipulated time and standard.

Once you have analyzed the causes of deviation, it becomes easy to identify the right corrective measures. Corrective actions help organizations reach their goals and prevent the same problems from reappearing.

When the actual performance matches with the standard, there is no need to take corrective actions but when they do not match taking corrective action is essential to bring organizational activities in the right direction.

Read Next: Effective Control System

Sajan Kushmi is a content writer with more than 4 years of experience. He holds BIM Degree. He write on the topics related to Management, Marketing, and Entrepreneurship.